Our Capabilities

Quality

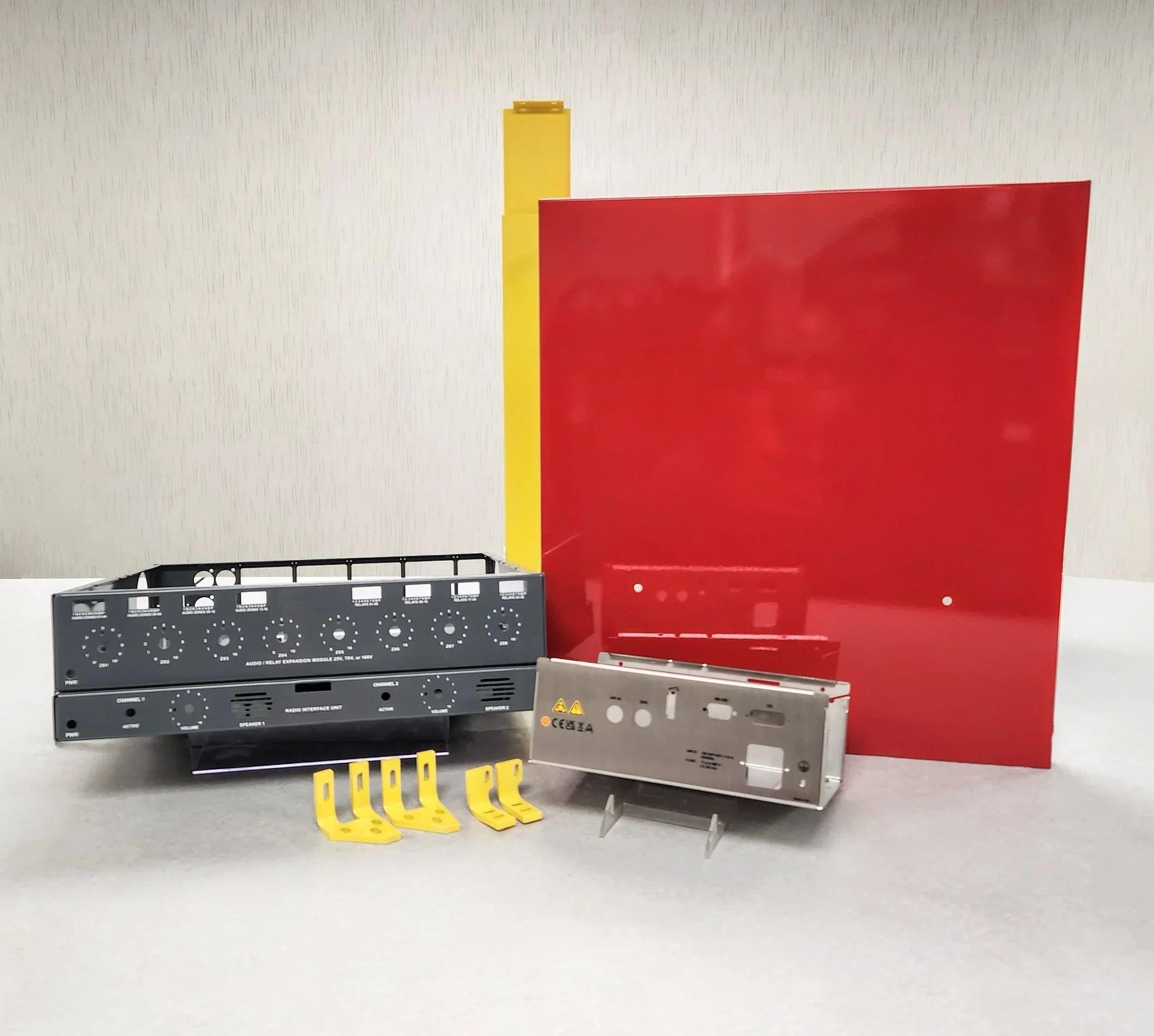

At inMetal, quality is the foundation of everything we do. Whether it's a simple bracket, a complex chassis, or a large weldment, every project receives the same level of meticulous attention, care, and dedication to excellence. Our team of experienced professionals, backed by decades of industry knowledge, conducts thorough in-process and final quality inspections to ensure accuracy at every stage of production.

From your initial Sales contact through the production process and delivery, inMetal provides thorough oversight, ensuring consistency, precision and exceptional quality every step of the way.

As an ISO 9001:2015 certified company, we maintain strict quality control standards to consistently meet—and often exceed—our customers’ expectations.

Engineering

At inMetal, we specialize in value-added, collaborative DFM (Design for Manufacturability) to improve the quality, performance, and cost-effectiveness of your sheet metal projects.

Our engineering team – made up of seasoned sheet metal mechanics with decades of hands-on experience – works closely with you to bring your designs to life. Whether you’re working from a fully developed CAD model or an initial concept sketch, we have the expertise to refine and optimize your designs for manufacturability, performance, and cost.

With a deep understanding of both the practical and theoretical aspects of sheet metal fabrication, we employ advanced CAD and CAM software to ensure your parts meet technical requirements, stay on schedule, and align with your budget – while upholding the highest standards of quality and craftsmanship.

We support projects of all sizes and complexities — from a simple bracket to a complex multi-component assembly — with the same level of precision, care, and attention to detail.

Facilities

InMetal is a leading provider of precision sheet metal fabrication and assembly, offering custom solutions from our 40,000 sq. ft. facility in Sharon, MA, conveniently located off Route 95.